A. Lange & Söhne crown the year of its jubilee

The Saxon manufacture finishes the year of its jubilee in beauty with a superb Handwerkskunst limited edition of 30 pieces of the 1815 Tourbillon. A fine watchmaking timepiece as beautiful as complex that celebrates the art of engraving and will be exhibited at the next SIHH in Geneva.

The 1815 TOURBILLON is the first A. Lange & Söhne watch that combines a stop-seconds device for the tourbillon and the ZERO-RESET mechanism. At the close of the anniversary year that commemorates the 200th birthday of Ferdinand Adolph Lange, this paragon of precision timekeeping is being presented in a limited HANDWERKSKUNST edition featuring extraordinary dial and movement decorations.

Handwerkskunst, the German word for “artisanship”, is an attribute of distinction that A. Lange & Söhne has been using since 2011 to identify special limited-edition watches whose dials and movements are endowed with rare finissage and engraving techniques. On 7 December 2015, the eminent Saxon manufactory is presenting the 1815 TOURBILLON HANDWERKSKUNST, a new model that not only stands out with exceptional decorative elements, but also unites two patented mechanisms. The ZERO-RESET function launched in 1997 by A. Lange & Söhne is paired with the stop-seconds device for the tourbillon that was introduced in 2008. Together, these mechanisms make it possible to stop and set the timepiece with one-second accuracy.

Limited to 30 watches, the special-edition model is available in a pink-gold case with a diameter of 39.5 millimetres. A. Lange & Söhne’s fifth HANDWERKSKUNST edition is a precious homage to Ferdinand Adolph Lange, the great Saxon watchmaking pioneer whose 200th birthday is being memorialised this year.

The main difference versus the model presented in 2014 is the dial. It is made of black-rhodiumed pink gold and decorated with elegant tremblage engraving. The engraver who uses this technique sculpts the material with a specially crafted lining burin to achieve a uniform, fine granular structure. The relief elements on the dial, including the prominent arced brand logo and the numerals, are later polished to a mirror gloss and contrast prominently against the dark background. An aperture in the dial reveals the large one-minute tourbillon. The tourbillon bridge and the upper part of the cage are black-polished: this is one of the most elaborate and time-consuming finissage techniques.

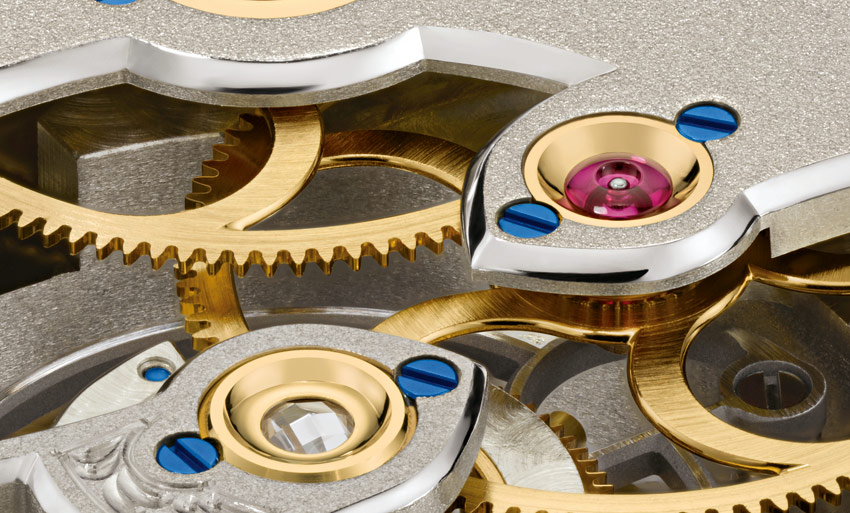

Mechanical precision is reflected in every detail of the lavishly decorated L102.1 manufacture calibre. The elegantly curved shape of the newly designed three-quarter plate is a special hallmark. Thanks to generous cut-outs, the tourbillon with the patented stop mechanism is easily visible from the movement side as well, as are the spring barrel and parts of the wheel train. The grained surface of the German silver plate is inspired by historic pocket watches. Bevel-polishing reentrant angles is a particular challenge. This task can only be performed manually with a sharp, specially designed tool. The fourth-wheel bridge is pierced to provide a better view of the tourbillon. Just like the plate and the caseback, it is endowed with artistic engravings. The diamond endstone of the tourbillon vibrantly accentuates the movement decorations.