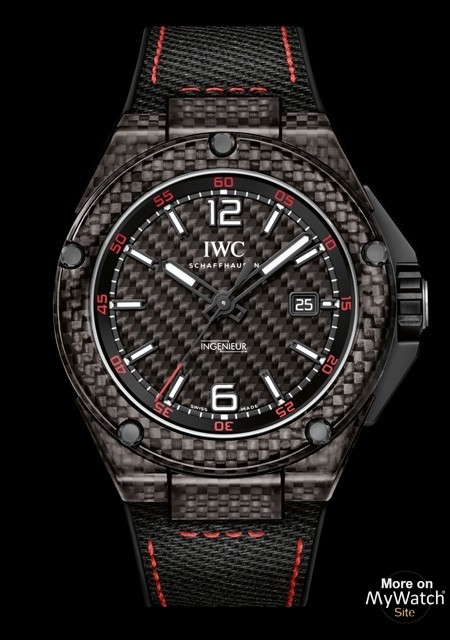

Ingenieur Automatic Carbon Performance

IW322402

| Brand : | IWC |

| Collection : | Ingenieur |

| Model : | Ingenieur Automatic Carbon Performance |

| Reference : | IW322402 |

| Nber of pieces : | 100 |

| Complement : | Carbon Fibers - Rubber and Textile Strap |

| Year : | 2013 |

| Is not commercialised any more | |

PDF INDEX CARD

-

Brand : IWC Collection : Ingenieur Model : Ingenieur Automatic Carbon Performance Reference : IW322402 Nber of pieces : 100 Complement : Carbon Fibers - Rubber and Textile Strap Year : 2013 Is not commercialised any more List Price : On request Diameter : 46 mm Thickness : 14.5 mm Styles : Sporty Types : Self-winding Calibre : 80110 Complication : Stop second mechanism Case material : Carbon fibers Case peculiarity : Screwed-down crown Engraving on case back “ONE OUT OF 100” Shape : Round Water-resistance : 120 meters Dial : Carbon fibers Dial color : Black Display : Luminescent hands Indexes : Arabic numerals Baton-type Luminescent Glass : Antireflective coating Sapphire Strap material : Rubber Textile Strap color : Black/Red Strap clasp : Pin buckle + More characteristics : MovementFrequency: 28.800 A/h/4HzJewels: 28Power reserve:44 h

Dial

Red numerals for the seconds

Pin buckle in titanium

DESCRIPTION

In 2013 IWC Schaffhausen starts a 3-year period as Official Engineering Partner of the MERCEDES AMG PETRONAS Formula One™ Team. Worldwide, the two companies stand for outstanding craftsman ship, innovation and performance engineering. To mark their cooperation, IWC presents a new timepiece in a carbon case. Available with either red or yellow design elements, the Ingenieur Automatic Carbon Performance is limited to 100 watches in each version.

When the red lights go out in front of the new MERCEDES AMG PETRONAS Formula One™ Team car in Melbourne for the first time, it signals the start of the 2013 Grand Prix season. Watching on intently will be a television audience in the tens of millions. And they will not be alone. Behind the scenes, a practised team of racing strategists and technicians will scrutinize every detail of the technical data streaming across their monitors. Have they got the technical parameters right ' Has all the effort been worth it ' And have all the months of calculations paid off ' The set-up of a Formula One™ racing car is cutting-edge precision work. Like the engineers at MERCEDES AMG PETRONAS, the designers, technicians and master watchmakers at IWC Schaffhausen work tirelessly to achieve a level of perfection known to both companies as performance engineering. In 2013 IWC is launching a timepiece that underscores its commitment as Official Engineering Partner of the MERCEDES AMG PETRONAS Formula One™ Team. The material used for the outer case is demanding, and the way in which it is processed only confirms IWC’s reputation as a manufacturer of timepieces of the very highest quality.CARBON – A HALLMARK MATERIAL IN FORMULA ONE™In the early 1980s, the use of carbon fibre revolutionized the manufacture of Formula One™ racing cars. No other material is as suitable as carbon for making the safety shell (monocoque) and bodywork. It is twice as rigid as steel and, volume for volume, just a fifth of the weight. A For mula One™ car monocoque consists of up to twelve layers of carbon-fibre matting and weighs less than 60 kilograms. The material is extremely rigid, which makes the carbon shell practically indestructible and plays a key role in the safety concept behind modern Formula One™. Carbon has become a hallmark of Formula One™ and at the same time a symbol of state-of-the-art materials innovation. Today, even the steering wheels found in racing cars are made mainly of carbon. So it seems only apt that IWC Schaffhausen should unveil a new timepiece in a carbon case to mark its cooperation with MERCEDES AMG PETRONAS: the Ingenieur Automatic Carbon Performance (Ref. IW322401, Ref. IW322402). The three-part outer case is based on the same principles as those used for the monocoque body of a racing car. Fibre matting is soaked in epoxy resin, moulded to the desired shape and then baked at a high temperature with overpressure. Finally, the resin is cured. A closer look at the webbing reveals individual fibres five times finer than a human hair. The black dial of the Ingenieur Automatic Carbon Performance is coated with carbon-fibre webbing in a twill weave: each strand of the weft thread is woven twice over and twice under a warp strand. This produces the characteristic pattern found on the steering wheel of the MERCEDES AMG PETRONAS Formula One™ racing car. The black carbon-fibre webbing complements the authenticFormula One™ look perfectly and gives the watch a dynamic surface with the added dimension of depth.DESIGN CUES BY WATCH DESIGNER GÉRALD GENTAThe five screws securing the outer case and carbon bezel to the waterresistant titanium inner case further enhance the technical look and feel of the Ingenieur Automatic Carbon Performance. The screw heads are a reinterpretation of Gérald Genta’s design language. He created the legendary Ingenieur SL (Ref. 1832), which was housed in a sporty steel case and launched in 1976. It has remained one of the watch industry’s great designs to this day. Taking his inspiration from a diving helmet, Genta made no attempt to conceal the screws and bores integral to the design, and placed them in full view on the bezel. Together with the lightning-bolt logo, the bores in the Ingenieur SL’s bezel have become a hallmark of the Ingenieur watch family. In much the same way that contemporary diving equipment influenced Gérald Genta, IWC’s design technicians have now taken many of their ideas from Formula One™. The classic range of materials traditionally found in a Formula One™racing car inspired the choice of materials for the Ingenieur Automatic Carbon Performance: carbon for the case and dial; ceramic for the crown, crown protection and screw heads; titanium for the screws; and, finally, rubber for the strap with its textile inlay. The strap has signal-yellow or red thread stitches reminiscent of the yellow stripes on the outer walls of soft slicks and the red stripes found on super-soft slicks used in Formula One™. In motor racing’s leading discipline, the choice of tyres is strategically decisive. The colours help spectators to identify the six different kinds of tyres more easily. The stitching on the strap matches the colour of the yellow or red numerals showing seconds on the flange, which differ in the two versions of the Ingenieur Automatic Carbon Performance. The rotor can be seen at work through the transparent sapphire-glass back, and was modelled on the pistons in a Formula One™ racing car. In this case, the engine is the IWC-manufactured 80110-calibre movement with the Pellaton automatic winding sysstem. The powerful drive ticks away reliably and has a 44-hour power reserve.QUALIFYING FOR WATCHESWhen a Formula One™ driver hurtles round the track at speeds of up to 300 kph, he encounters impacts and vibrations that could – literally – leave him shaken up. In the bends, his body is subjected to centrifugal forces of up to five times the pull of gravity. Without a muscular physique and an effective suspension, it would be virtually unbearable. In the Ingenieur Automatic Carbon Performance, the job of counteracting impacts and vibrations is handled by the integrated shock-absorption system. It means the 80110 calibre is one of the most robust movements to make it through IWC’s gruelling series of tests, which simulate everything that can happen to a watch in both normal and extreme circumstances. The process known as “qualifying” in Formula One™ has similarities with “qualification” at IWC. In the workshops in Schaffhausen, the term stands for an extremely tough testing programme lasting several months. Only timepieces that emerge successful from countless tests involving impact, abrasion, climate, corro sion, UV and practice will make it to the marketplace, where they are measured against the rest of the competition in the field of haute horlogerie. The Ingenieur Automatic Carbon Performance has passed with flying colours. This impressive example of high technology is limited to 100 examples each with yellow or red numerals for the seconds and stitching on the strap. The case back ring bears the engraving “ONE OUT OF 100”.IWC SCHAFFHAUSENWith a clear focus on technology and development, the Swiss watch manufacturer IWC Schaffhausen has been producing timepieces of lasting value since 1868. The company has gained an international reputation based on a passion for innnovative solutions and technical ingenuity. One of the world’s leading brands in the luxury watch segment, IWC crafts masterpieces of haute horlogerie at its finest, combining supreme precision with exclusive design.FURTHER INFORMATIONIWC SchaffhausenBranch of Richemont International SAUwe LiebmingerDepartment Manager Public RelationsMobile +41 (0)79 957 72 52Email uwe.liebminger@iwc.comInternet www.iwc.com/pressDOWNLOADSIllustrative material marking the launch of the new 2013 Ingenieur watch collection from IWC can be downloaded free of charge at www.photopress.ch/image/IWC/SIHH/2013

In 2013 IWC Schaffhausen starts a 3-year period as Official Engineering Partner of the MERCEDES AMG PETRONAS Formula One™ Team. Worldwide, the two companies stand for outstanding craftsman ship, innovation and performance engineering. To mark their cooperation, IWC presents a new timepiece in a carbon case. Available with either red or yellow design elements, the Ingenieur Automatic Carbon Performance is limited to 100 watches in each version.

When the red lights go out in front of the new MERCEDES AMG PETRONAS Formula One™ Team car in Melbourne for the first time, it signals the start of the 2013 Grand Prix season. Watching on intently will be a television audience in the tens of millions. And they will not be alone. Behind the scenes, a practised team of racing strategists and technicians will scrutinize every detail of the technical data streaming across their monitors. Have they got the technical parameters right ' Has all the effort been worth it ' And have all the months of calculations paid off ' The set-up of a Formula One™ racing car is cutting-edge precision work. Like the engineers at MERCEDES AMG PETRONAS, the designers, technicians and master watchmakers at IWC Schaffhausen work tirelessly to achieve a level of perfection known to both companies as performance engineering. In 2013 IWC is launching a timepiece that underscores its commitment as Official Engineering Partner of the MERCEDES AMG PETRONAS Formula One™ Team. The material used for the outer case is demanding, and the way in which it is processed only confirms IWC’s reputation as a manufacturer of timepieces of the very highest quality.CARBON – A HALLMARK MATERIAL IN FORMULA ONE™In the early 1980s, the use of carbon fibre revolutionized the manufacture of Formula One™ racing cars. No other material is as suitable as carbon for making the safety shell (monocoque) and bodywork. It is twice as rigid as steel and, volume for volume, just a fifth of the weight. A For mula One™ car monocoque consists of up to twelve layers of carbon-fibre matting and weighs less than 60 kilograms. The material is extremely rigid, which makes the carbon shell practically indestructible and plays a key role in the safety concept behind modern Formula One™. Carbon has become a hallmark of Formula One™ and at the same time a symbol of state-of-the-art materials innovation. Today, even the steering wheels found in racing cars are made mainly of carbon. So it seems only apt that IWC Schaffhausen should unveil a new timepiece in a carbon case to mark its cooperation with MERCEDES AMG PETRONAS: the Ingenieur Automatic Carbon Performance (Ref. IW322401, Ref. IW322402). The three-part outer case is based on the same principles as those used for the monocoque body of a racing car. Fibre matting is soaked in epoxy resin, moulded to the desired shape and then baked at a high temperature with overpressure. Finally, the resin is cured. A closer look at the webbing reveals individual fibres five times finer than a human hair. The black dial of the Ingenieur Automatic Carbon Performance is coated with carbon-fibre webbing in a twill weave: each strand of the weft thread is woven twice over and twice under a warp strand. This produces the characteristic pattern found on the steering wheel of the MERCEDES AMG PETRONAS Formula One™ racing car. The black carbon-fibre webbing complements the authenticFormula One™ look perfectly and gives the watch a dynamic surface with the added dimension of depth.DESIGN CUES BY WATCH DESIGNER GÉRALD GENTAThe five screws securing the outer case and carbon bezel to the waterresistant titanium inner case further enhance the technical look and feel of the Ingenieur Automatic Carbon Performance. The screw heads are a reinterpretation of Gérald Genta’s design language. He created the legendary Ingenieur SL (Ref. 1832), which was housed in a sporty steel case and launched in 1976. It has remained one of the watch industry’s great designs to this day. Taking his inspiration from a diving helmet, Genta made no attempt to conceal the screws and bores integral to the design, and placed them in full view on the bezel. Together with the lightning-bolt logo, the bores in the Ingenieur SL’s bezel have become a hallmark of the Ingenieur watch family. In much the same way that contemporary diving equipment influenced Gérald Genta, IWC’s design technicians have now taken many of their ideas from Formula One™. The classic range of materials traditionally found in a Formula One™racing car inspired the choice of materials for the Ingenieur Automatic Carbon Performance: carbon for the case and dial; ceramic for the crown, crown protection and screw heads; titanium for the screws; and, finally, rubber for the strap with its textile inlay. The strap has signal-yellow or red thread stitches reminiscent of the yellow stripes on the outer walls of soft slicks and the red stripes found on super-soft slicks used in Formula One™. In motor racing’s leading discipline, the choice of tyres is strategically decisive. The colours help spectators to identify the six different kinds of tyres more easily. The stitching on the strap matches the colour of the yellow or red numerals showing seconds on the flange, which differ in the two versions of the Ingenieur Automatic Carbon Performance. The rotor can be seen at work through the transparent sapphire-glass back, and was modelled on the pistons in a Formula One™ racing car. In this case, the engine is the IWC-manufactured 80110-calibre movement with the Pellaton automatic winding sysstem. The powerful drive ticks away reliably and has a 44-hour power reserve.QUALIFYING FOR WATCHESWhen a Formula One™ driver hurtles round the track at speeds of up to 300 kph, he encounters impacts and vibrations that could – literally – leave him shaken up. In the bends, his body is subjected to centrifugal forces of up to five times the pull of gravity. Without a muscular physique and an effective suspension, it would be virtually unbearable. In the Ingenieur Automatic Carbon Performance, the job of counteracting impacts and vibrations is handled by the integrated shock-absorption system. It means the 80110 calibre is one of the most robust movements to make it through IWC’s gruelling series of tests, which simulate everything that can happen to a watch in both normal and extreme circumstances. The process known as “qualifying” in Formula One™ has similarities with “qualification” at IWC. In the workshops in Schaffhausen, the term stands for an extremely tough testing programme lasting several months. Only timepieces that emerge successful from countless tests involving impact, abrasion, climate, corro sion, UV and practice will make it to the marketplace, where they are measured against the rest of the competition in the field of haute horlogerie. The Ingenieur Automatic Carbon Performance has passed with flying colours. This impressive example of high technology is limited to 100 examples each with yellow or red numerals for the seconds and stitching on the strap. The case back ring bears the engraving “ONE OUT OF 100”.IWC SCHAFFHAUSENWith a clear focus on technology and development, the Swiss watch manufacturer IWC Schaffhausen has been producing timepieces of lasting value since 1868. The company has gained an international reputation based on a passion for innnovative solutions and technical ingenuity. One of the world’s leading brands in the luxury watch segment, IWC crafts masterpieces of haute horlogerie at its finest, combining supreme precision with exclusive design.FURTHER INFORMATIONIWC SchaffhausenBranch of Richemont International SAUwe LiebmingerDepartment Manager Public RelationsMobile +41 (0)79 957 72 52Email uwe.liebminger@iwc.comInternet www.iwc.com/pressDOWNLOADSIllustrative material marking the launch of the new 2013 Ingenieur watch collection from IWC can be downloaded free of charge at www.photopress.ch/image/IWC/SIHH/2013

-

Brand : IWC Collection : Ingenieur Model : Ingenieur Automatic Carbon Performance Reference : IW322402 Nber of pieces : 100 Complement : Carbon Fibers - Rubber and Textile Strap Year : 2013 Is not commercialised any more List Price : On request Diameter : 46 mm Thickness : 14.5 mm Styles : Sporty Types : Self-winding Calibre : 80110 Complication : Stop second mechanism Case material : Carbon fibers Case peculiarity : Screwed-down crown Engraving on case back “ONE OUT OF 100” Shape : Round Water-resistance : 120 meters Dial : Carbon fibers Dial color : Black Display : Luminescent hands Indexes : Arabic numerals Baton-type Luminescent Glass : Antireflective coating Sapphire Strap material : Rubber Textile Strap color : Black/Red Strap clasp : Pin buckle More characteristics : MovementFrequency: 28.800 A/h/4HzJewels: 28Power reserve:44 h

Dial

Red numerals for the seconds

Pin buckle in titanium